The working group sees itself in the unique position of being able to provide various development environments for many research, development, and teaching issues. Specifically, these are divided as follows:

Plastics laboratoryOpen areaClose area

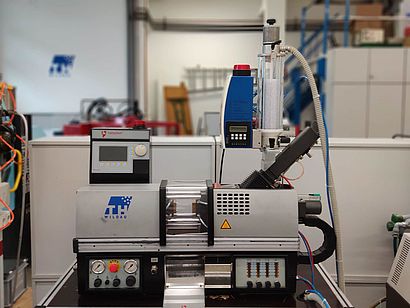

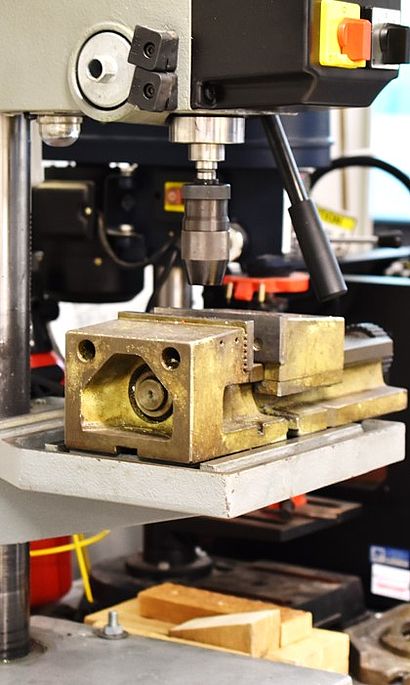

The continuous core of the working group is the plastics laboratory in room 15.050. The lab offers various work areas for skills within and outside plastic processing. Here you will find the WG's injection molding machines and a machining line for cutting processes (turning, milling, drilling, sawing, etc.). Additionally, there is a soldering station for assembling electronic setups, as well as various workstations that can be assigned as needed.

Equipment details:

-

DEMAG 100, 10000 t clamping force, 2000 bar injection pressure, 100 cm² build space, inlay process

-

Babyplast, 6000 t clamping force, 2000 bar injection pressure, 6 cm² build space, inlay process

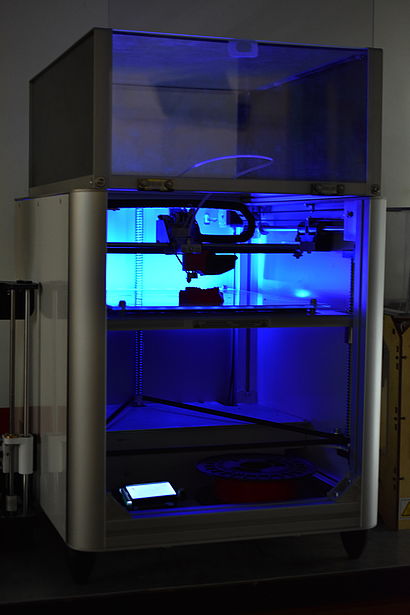

3D-print-laboratoryOpen areaClose area

FDM printers in detail:

-

Creatr HS (280x270x180 build space); layer height 0.1-0.3 mm

-

Creatr HS XL (270x270x590 build space); layer height 0.1-0.4 mm

-

Replicator 1 (225x145x150 build space); layer height 0.05-0.15 mm

-

Replicator 2 (246x152x155 build space); layer height 0.1-0.3 mm

-

Ultimaker S3 (230x190x200 build space); layer height 0.02-0.2 mm

- Bambu Lab P1S (256x256x256 build space)

- Bambu Lab X1 Carbon (256x256x256 build space)

SLA printers in detail:

-

Formlabs 1 (XY DPI 150 µm)

-

Anycubic Photon S (XY DPI 47 µm)

Materials:

-

PLA, PETG, TPU, ABS, ASA, PC, fluorescence, wood, etc.

-

UV 405nm light-sensitive resins

3D-metal-printerOpen areaClose area

Since December 2022, the working group also has access to a 3D metal printer. This can be used for "Selective Laser Melting" (SLM) of various metals and their alloys. Additionally, the "lab module" can be inserted into the build space of the metal printer to use additional powder materials alongside the powder system without extensive material changes.

Equipment details:

-

MPrint+ BOLDSERIES (150x150x150 build space); layer height 0.02-0.08 mm

-

Lab module within the MPrint+ (78x53x90 build space); layer height 0.02-0.08 mm

Materials:

-

Stainless steel material 1.4404

-

Other metals are possible (currently not available)

Xolography 3D printerOpen areaClose area

With the commissioning of a Xolography 3D printer, the working group has access to another modern printing technology where light beams of two different wavelengths are crossed to write structures into the volume of a material to create 3D objects. The improvement of material properties and the precision of the printing technology are particularly used in the production of optics, microfluidic systems, and medical implants.

Equipment details:

-

XOLO XUBE2 (build volume up to 80mm), light sheet width 50 μm, feature size down to 5 μm, 375 and 405 nm laser source

Medical technology laboratoryOpen areaClose area

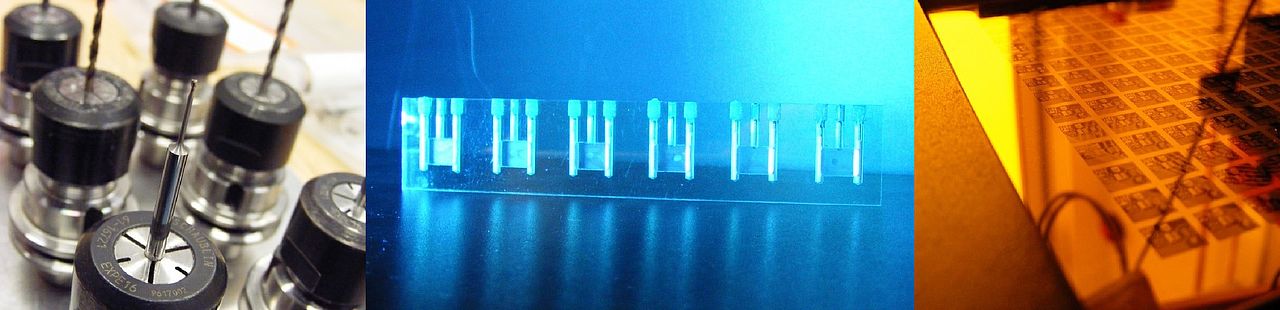

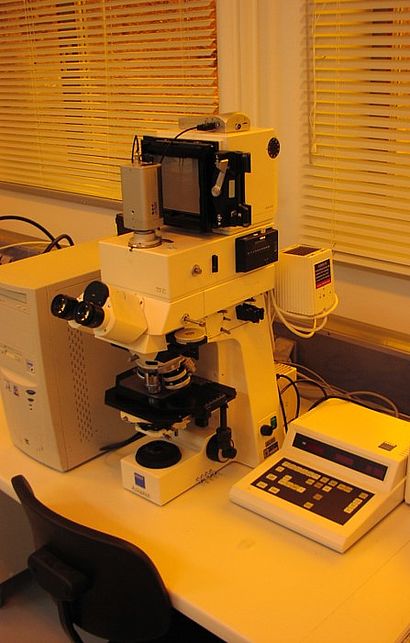

In the medical technology laboratory, you will find the KERN micro milling machine, which represents another cornerstone of the working group's capabilities. Through highly precise milling operations, complex microstructures can be realized for injection molding or direct use in the lab. Additionally, the lab is equipped with various optical instruments for thorough material inspection before and after manufacturing steps. A Dremel workstation is also available for manual post-processing within the established process chain.

Equipment details:

-

Kern micro milling machine MMP 2522 (positioning accuracy 1 µm, repeatability 2.5 µm, 3-axis milling, high-frequency spindle VSC 500-50000 min-1)

-

Keyence VW-6000 motion analysis microscope (high-speed recordings 24000 fps, 3D depth representation, universal zoom lens VH-Z100R 100-1000x)

-

Zeiss Axiophot fluorescent microscope (transmitted light microscope, digital video interface, 5-50x)

-

Zeiss Stemi 2000-C (stereomicroscope with photo adapter, transmitted and reflected light illumination, 0.65-5x)

CleanroomOpen areaClose area

The working group's cleanroom is unique and currently primarily serves teaching purposes. It includes workstations for coating, exposing, sputtering, wire bonding, wire testing, and etching. The cleanroom operates a mixed-mode system, allowing for local enhancement of the cleanroom class under the flow boxes as needed. In practice, this can create a cleanroom class FS 10000, approximately equivalent to ISO 7, while locally achieving FS 1000 / ISO 6.

Equipment details:

-

Exposure system (quartz vapor lamp)

-

Spin coater (manual)

-

PVD chamber

-

Langmuir-Blodgett

-

Furnace

-

Wet chemistry workstation for etching baths

-

Wire bonder

-

Pull tester

-

Needle tester

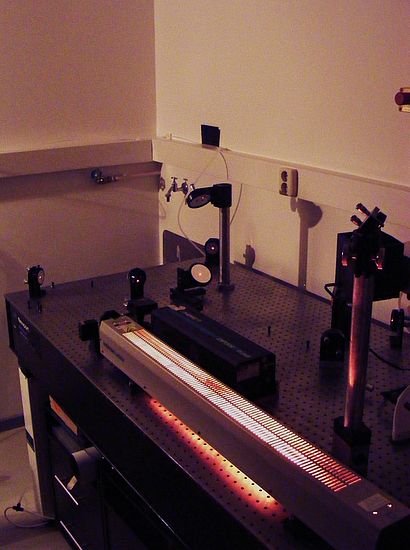

Laser laboratoryOpen areaClose area

In the WG's laser laboratory, there are two systems for vibration and deformation analysis that utilize electronic speckle pattern interferometry (ESPI). A unique feature here is the 2D ESPI, which has been modified through three doctoral theses into a so-called micro-ESPI. This allows for the observation and analysis of movements on a microscopic level.

Equipment details:

-

2D ESPI (Micro ESPI); Z-axis deformation, static measurement, tilting table for surface measurement possible

-

3D ESPI; XYZ-axis deformations and vibrations, dynamic and static measurements possible, suspension for measurements or beam path modification

Other machines and possibilitiesOpen areaClose area

- Lathe Drill machine

- Thermoforming machine

- Granulate extruder

- Plastic shredder system

- Thermal imaging via infrared camera

- PCB design

- Moldflow analysis

- Tensile test

- Charpy impact test

- Heat treatment

- ... and more